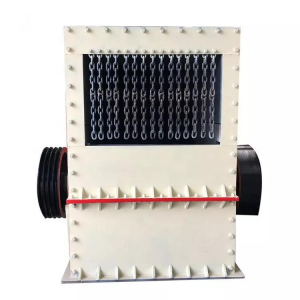

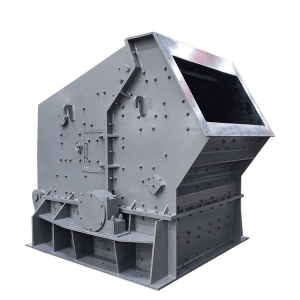

Hammer Crusher

Production Description

The hammer crusher is a crusher that crushes materials with a particle size of 600-1800 mm to 25 or below 25 mm. It is suitable for medium and fine crushing of medium-hard and brittle materials.

Feature:

1. Inlet large, high crushing chamber adapted material hardness, block degree, the product powder less

2. Materials vacant, broken power consumption

3. New hammer, impact force

4. Hammer shaft mounted adjustable, hammer, long life

5. Grid size is adjustable, controllable particle size, particle shape is good

6. Chassis can be flipped, maintenance more convenient

7. Square shank bolts, impact resistance, wear and tear

8. Compact, machine rigidity

9. Fight structure, handling, easy to install

10. The machine shocks, counter, strike (rock stone) fragmentation functions in a high production efficiency, mechanical abrasion is small, the overall efficiency significantly, widely used in artificial sand

Technical parameters

|

Model |

Rotor speed (r/min) |

Feed opening size (mm) |

Max feeding size (mm) |

Discharging size (mm) |

Capacity (t/h) |

Motor power (kw) |

Weight (t) |

|

PC300 × 200 |

1500 |

100*200 |

80 |

0-10 |

2-5 |

5.5 |

0.5 |

|

PC400×300 |

1500 |

145×295 |

100 |

0-30 |

5-8 |

7.5 |

0.9 |

|

PC600×400 |

1000 |

295×450 |

100 |

0-35 |

10-12 |

18.5 |

1.5 |

|

PC600×600 |

1000 |

295×570 |

100 |

0-35 |

12-18 |

45 |

2.14 |

|

PC800×600 |

1000 |

350×570 |

120 |

0-45 |

20-25 |

55 |

2.45 |

|

PC800×800 |

1000 |

350×850 |

120 |

0-45 |

35-45 |

55 |

3.05 |

|

PC1000×800 |

1000 |

580×580 |

200 |

0-45 |

25-40 |

110 |

6.5 |

|

PC1000×1000 |

1000 |

580×1060 |

200 |

0-45 |

40-80 |

132 |

7.59 |

|

PC 1250×800 |

750 |

650×850 |

200 |

0-45 |

20-50 |

132 |

11.7 |

|

PC1250×1250 |

750 |

650×1330 |

200 |

0-45 |

90-110 |

185 |

13.2 |

|

PC1400×1400 |

750 |

1050×1540 |

250 |

0-45 |

120-170 |

280 |

17.2 |

|

PC1600×1600 |

600 |

1500×1785 |

350 |

0-60 |

220-280 |

450 |

22.8 |

Product Show

Product details

Sale service

Modular design for convenient and fast installation, maintenance, relocation and tranportation.