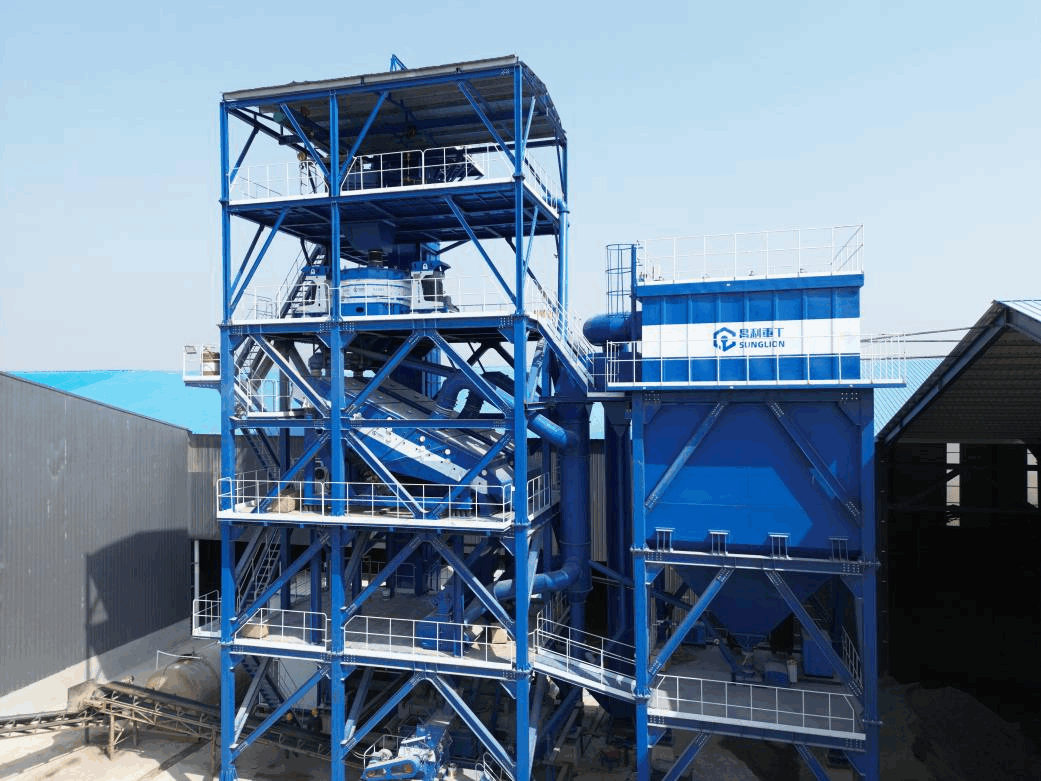

Dry sand making towers, as a modern sand making solution, are based on a dry production mode that integrates high-efficiency sand making, particle shape optimization, stone powder control, gradation adjustment, and environmentally friendly dust removal.

Core configuration:

Elevator: Lifts raw materials from the ground to the rooftop storage silo.

TLS1563 Sand Making Machine: Crushes and shapes stone materials to produce high-quality manufactured sand.

Vibrating Screen: Precisely screens mixed materials according to different particle sizes to ensure high-quality and stable finished sand.

Air Classifier: Precisely controls the stone powder content in the finished sand and achieves efficient separation of stone powder from qualified particles.

Humidifier: Suppresses dust, adjusts and stabilizes the moisture content of materials, and prevents material segregation and clogging.

Pulse Jet Dust Collector: Efficiently collects and filters dust generated during the production process, achieving clean production and compliant dust emissions.

Core Capacity: This production line boasts a flexible capacity of 200 tons per hour for pure sand production and 400 tons per hour for combined sand and gravel production. The system employs a fully closed-loop design, achieving intensive production and environmental compliance, ensuring stable and efficient operation.

Choosing a production line is choosing a long-term business partner. Changli Group, with 43 years of technology and experience, cordially invites you to visit our site and witness the true strength of this “wealth-creating production line.” Feel free to contact us anytime to schedule a trial run!