Processed Materials: Hard rocks: granite, basalt, river pebbles, iron ore, etc. (compressive strength ≤350MPa); Medium-hard rocks: limestone, dolomite, sandstone, shale, etc.; Recyclable resources: construction waste, concrete blocks, industrial waste residue, etc.

Max.Feed Size: 500MM

BLURB

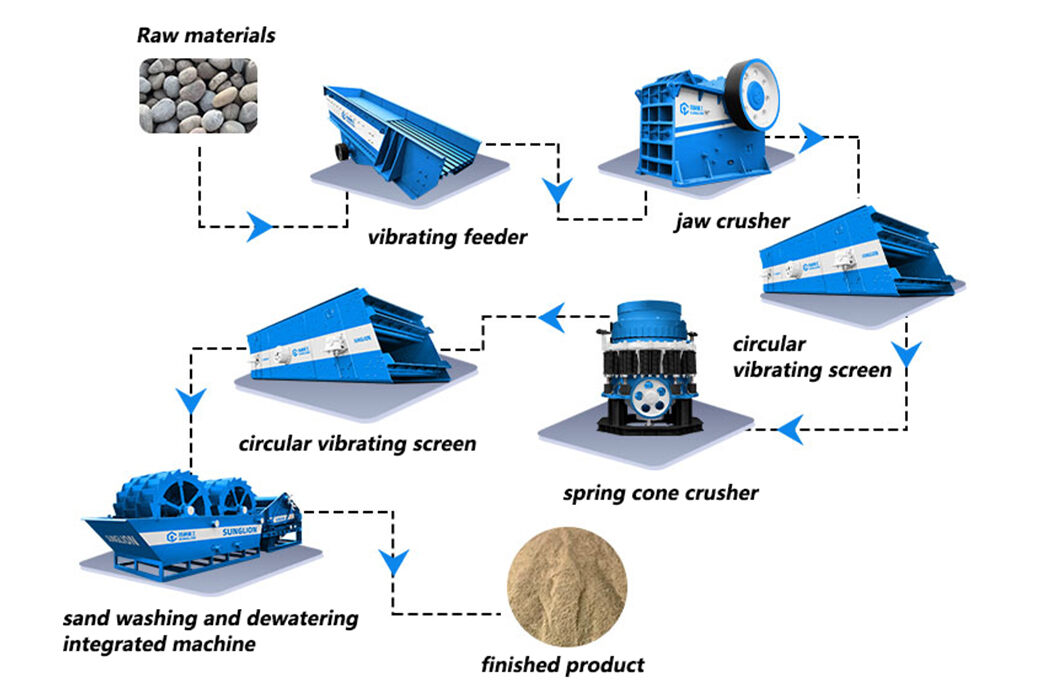

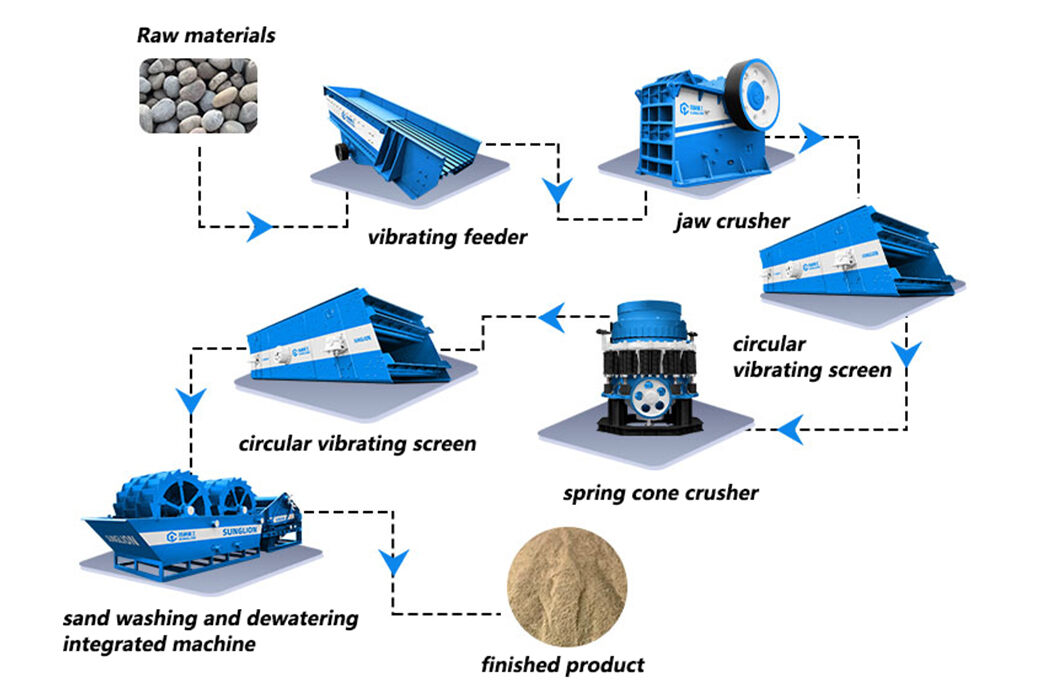

The mining crushing and sand making production line is a comprehensive production system that integrates crushing, sand making, screening and sand washing.The demand for high-quality sand and gravel is surging, and pebbles, due to their abundant reserves, have become a high-quality raw material. Matching the characteristics of pebbles to the production line configuration is key to efficient output.

Vibrating feeder: Used to achieve uniform and continuous conveying of pebbles, ensuring stable process operation.

Jaw crusher: A key piece of equipment for coarse crushing, with a large crushing ratio and high capacity.

Spring cone crusher: The core equipment for medium crushing, featuring excellent wear resistance and particle size uniformity.

Circular vibrating screen: Finished product grading equipment used for secondary screening of crushed materials, accurately separating stones of different sizes from sand to be washed.

Integrated sand washing and dewatering machine: Efficiently removes mud and impurities from sand, rapidly reducing the moisture content of washed sand and minimizing the storage space required for finished sand.

|

Model |

Product name |

Product Model |

Quantity |

Capacity (t/h) |

Power (kW) |

Max feeding size (mm) |

|

MCW-CL200 |

Jaw crusher |

PE600X900 |

2sets |

50-180 |

75 |

500 |

|

Spring cone crusher |

PY1400S-X |

1set |

120-250 |

220 |

112 |

|

|

Integrated sand washing and dewatering machine

|

2LX3624-120-2442(D) |

1set |

150-220 |

81 |

/ |

|

|

vibrating feeder |

ZSW420X110 |

1set |

120-210 |

15 |

650 |

|

|

Vibrating screen |

3YK1860 |

1set |

100-250 |

22 |

400 |

|

|

2YK1860 |

1set |

100-300 |

22 |

400 |