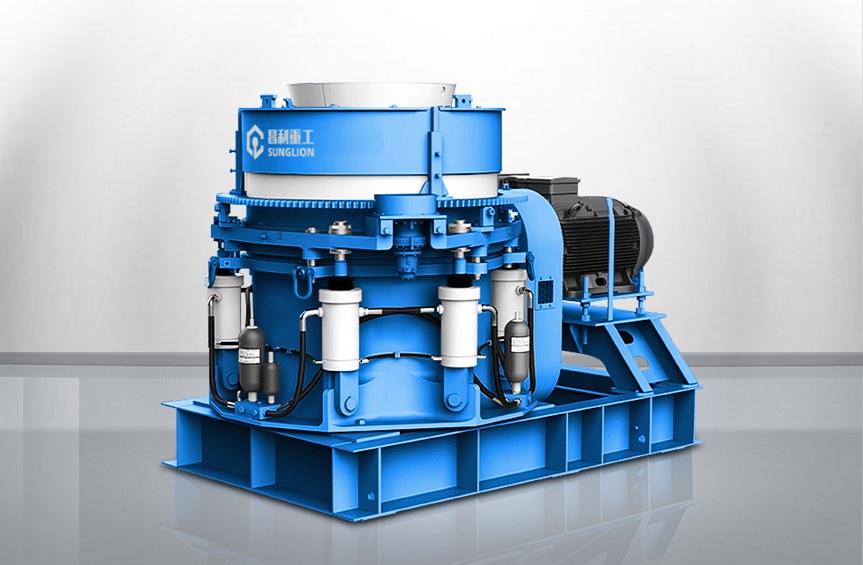

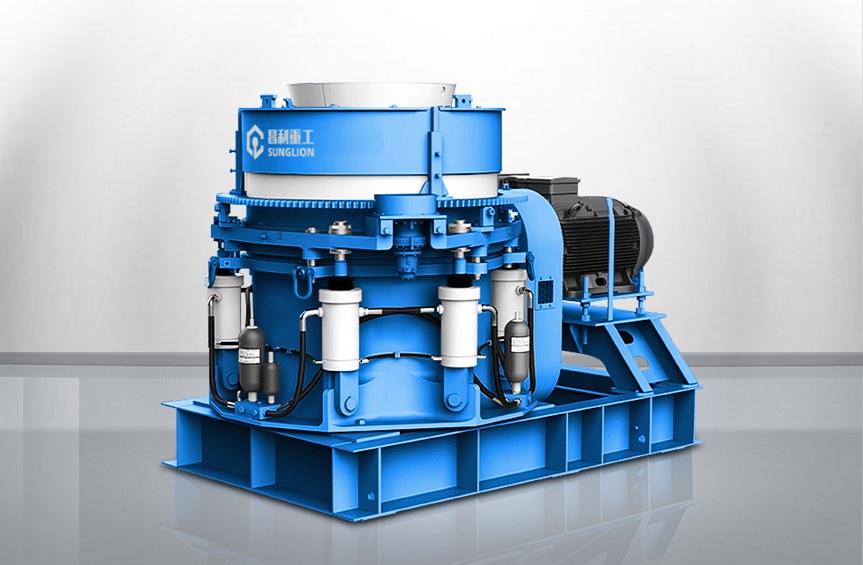

pMaximum Feeding Size: 350cm Processing capacity: 1100/h

BLURB

HP series multi-cylinder hydraulic cone crushers are suitable for crushing various medium and high hardness ores and rocks. They feature low energy consumption, high crushing force, high reliability, large production capacity, high degree of automation, simple operation and maintenance, good product particle size, and low maintenance cost of vulnerable parts.

The moving core of the crusher rotates and reciprocates under the action of the eccentric sleeve. This motion causes the liners to squeeze and rub against the material, thus moving the material between the liners and the concave surface. According to the theory of interparticle crushing, the material is subjected to forces from multiple directions, eventually forming stable particles. Particles that meet the discharge requirements are discharged through the reciprocating gap between the liners, while the remaining material continues to be crushed until it reaches the required particle size.

|

Model |

Cavity |

Diameter of bottom end of conical crushing head (mm) |

Feeding opening size (mm) |

Max. feeding size (mm) |

Nominal capacity in t/h with crusher running at CSS (mm) |

Crushing capacity (t/h) |

Motor power (kW) |

Host weight (t) |

|

HPM200 |

C1 |

900 |

185 |

145 |

22 |

160~250 |

160 |

11 |

|

C2 |

125 |

100 |

18 |

145~250 |

||||

|

C3 |

95 |

75 |

14 |

120~250 |

||||

|

F1 |

76 |

60 |

12 |

108~210 |

||||

|

F2 |

54 |

45 |

10 |

81~210 |

||||

|

HPM300 |

C1 |

1100 |

235 |

190 |

26 |

230~445 |

220 |

20 |

|

C2 |

211 |

170 |

20 |

200~445 |

||||

|

C3 |

150 |

120 |

16 |

180~445 |

||||

|

C4 |

107 |

85 |

14 |

160~220 |

||||

|

F1 |

53 |

40 |

12 |

140~220 |

||||

|

HPM400 |

C1 |

1400 |

299 |

240 |

35 |

270~630 |

315 |

27 |

|

C2 |

252 |

200 |

25 |

252~630 |

||||

|

C3 |

198 |

160 |

25 |

243~630 |

||||

|

C4 |

111 |

190 |

18 |

210~630 |

||||

|

F1 |

92 |

75 |

15 |

162~370 |

||||

|

F2 |

52 |

40 |

13 |

126~370 |

||||

|

HPM500 |

C1 |

1500 |

335 |

270 |

38 |

365~790 |

400 |

40 |

|

C2 |

286 |

230 |

30 |

328~790 |

||||

|

C3 |

204 |

165 |

22 |

280~790 |

||||

|

C4 |

133 |

105 |

20 |

202~450 |

||||

|

F1 |

95 |

75 |

16 |

175~450 |

||||

|

F2 |

52 |

42 |

8 |

158~450 |

||||

|

HPM650 |

C1 |

|

328 |

262 |

30 |

386~790 |

500 |

|

|

C2 |

279 |

225 |

25 |

348~790 |

||||

|

C3 |

196 |

175 |

20 |

300~790 |

||||

|

F1 |

106 |

85 |

13 |

280~530 |

||||

|

F2 |

52 |

42 |

9 |

220~530 |

||||

|

HPM800 |

C1 |

2000 |

353 |

280 |

38 |

616~1100 |

630 |

70 |

|

C2 |

297 |

240 |

38 |

522~1100 |

||||

|

C3 |

267 |

214 |

25 |

495~1100 |

||||

|

C4 |

219 |

175 |

22 |

380~1100 |

||||

|

F1 |

155 |

125 |

20 |

328~730 |

||||

|

F2 |

92 |

75 |

16 |

270~730 |