Productivity: 60-180 M3/h Mixing Host: JS1000-JS3000

BLURB

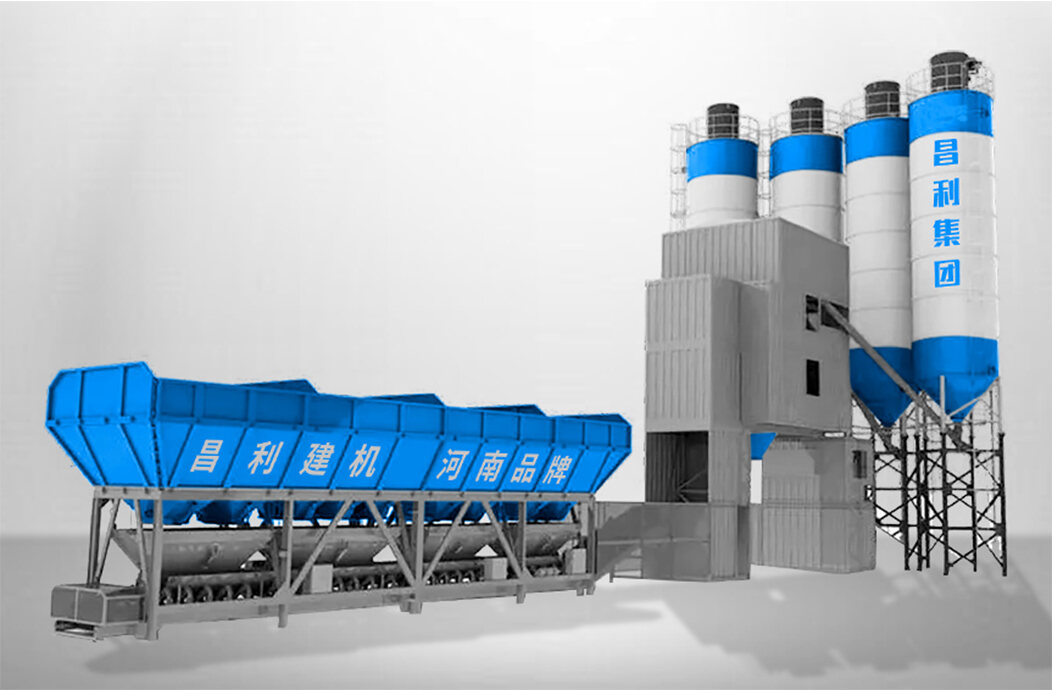

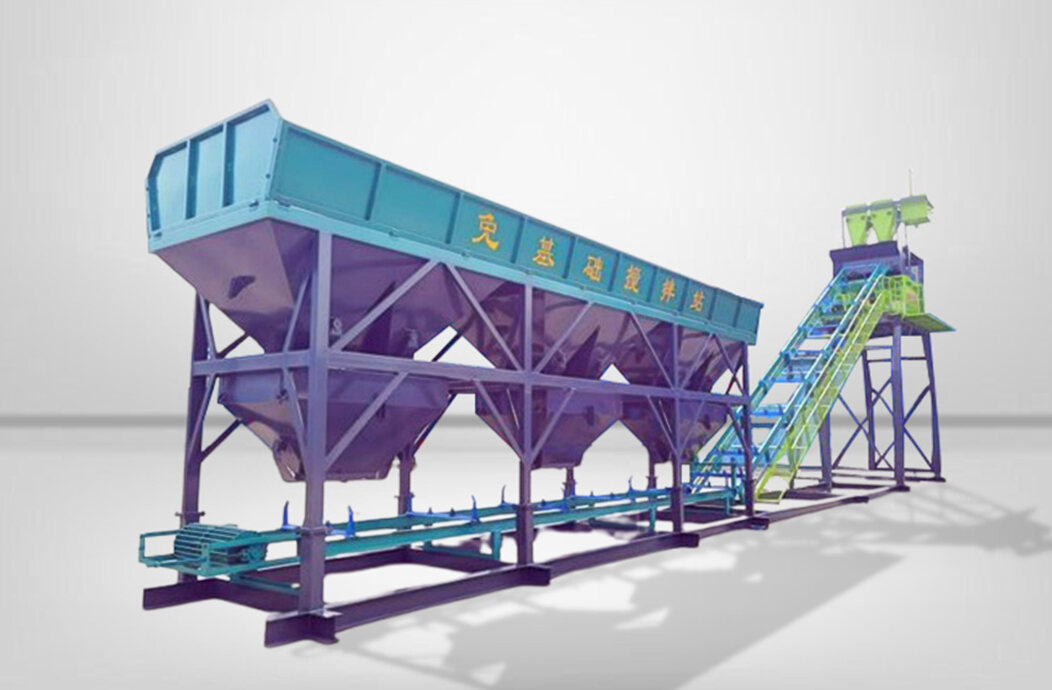

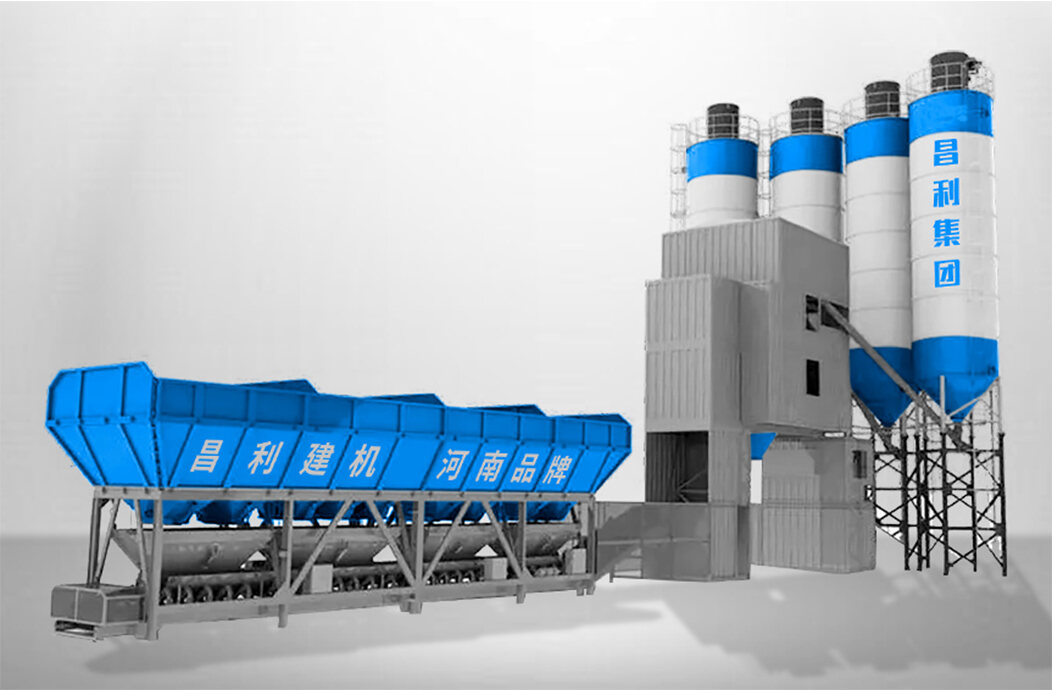

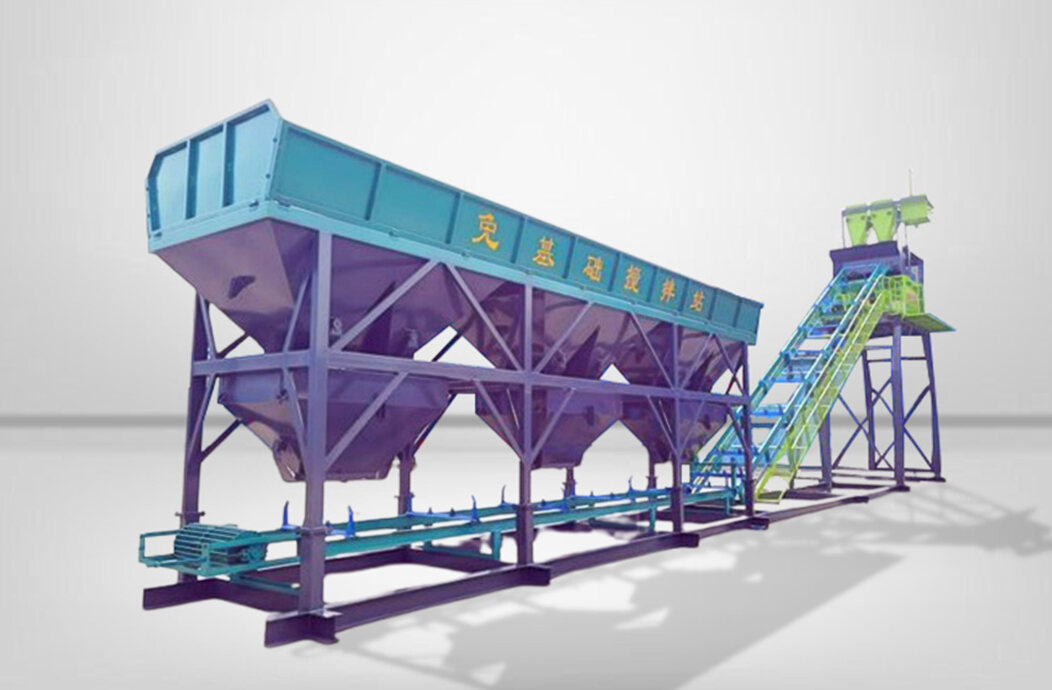

The concrete batching plant is a simple small-scale concrete mixing plant equipment that adopts an automatic hopper feeding method. It is a semi-automatic/fully automatic concrete mixing plant system composed of a double horizontal shaft forced mixer, feeding, batching, electrical control, and steel structure.

The concrete batching plants are divided into three types: stationary, foundation free, and mobile, with simple structure. Adopting newly designed electronic weighing, microcomputer control, digital display and other control technologies, electronic weighing is equipped with buffering devices and automatic compensation functions, with high measurement accuracy.

Application areas: Widely used in large and medium-sized prefabricated component factories, as well as industrial and civil construction projects such as highways, bridges, water conservancy, and docks.

Conveying System: Employs a fully sealed device; the discharge port is softly connected to the metering hopper; the receiving port has an adjustable angle deviation.

Storage System: The cement silo adopts a modular design and a combined structure; it is equipped with level gauges and a dust removal system.

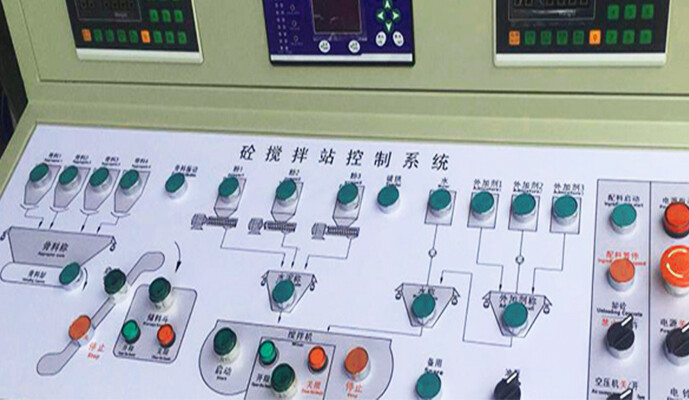

Control System: Utilizes imported components; remote management; proportioned storage; automatic drop compensation.

|

Model |

FHZS60 |

FHZS90 |

FHZS120 |

FHZS180 |

|

Theoretical Productivity(m³/h) |

60 |

90 |

120 |

180 |

|

Concrete Mixer |

JS1000 |

JS1500 |

JS2000 |

JS3000 |

|

Kinds Of Aggregate |

3 |

4 |

4 |

4 |

|

Maximum Aggregate Size(mm) |

80 |

80 |

80 |

80 |

|

Discharge Height(mm) |

3800 |

3800 |

3800 |

3800 |